I've been busy working on the layout over the last week or so - although it doesn't feel like model railroading. Actually, doesn't feel a whole lot different than the painting we've been doing in other parts of the house.

But all the IKEA leg sections have gotten two coats of paint, the shelves have been stained and varnished and most of those components are in the basement awaiting assembly.

I also have some IKEA cabinets - those have gotten a coat of wood prep.

On the docket for this evening is sanding the cabinets and getting a coat of paint on them.

I've also worked up a benchwork plan and plan to start construction sometime over the July 4th week which promises to be a little slow at the office.

Thursday, June 28, 2018

Wednesday, June 20, 2018

Tuesday, June 19, 2018

A truly universal tool

Ever wonder what the original universal tool might be?

It just may be the file.

Beyond the obvious purpose to either smooth or file metal, plastic or wood to shape consider you can also:

1. Cut material to length (using sharp corners)

2. Hammer nails or brads - provided it's a beefy enough file

3. Use it to pry two or more boards apart

4. Open a can of paint with it

And, of course, once the paint can is open, you can work most efficiently by using it to stir the paint.

I'm starting a new trend here, that I hope will catch on. Despite my known tool-alcoholic tendency, I'm turning over a new leaf - I think I can get by with two or three tools -

something that makes holes, such as a drill; drives screws (hey, a cordless "drill" also works - even more efficiency!) and, of course:

It just may be the file.

Beyond the obvious purpose to either smooth or file metal, plastic or wood to shape consider you can also:

1. Cut material to length (using sharp corners)

2. Hammer nails or brads - provided it's a beefy enough file

3. Use it to pry two or more boards apart

4. Open a can of paint with it

And, of course, once the paint can is open, you can work most efficiently by using it to stir the paint.

I'm starting a new trend here, that I hope will catch on. Despite my known tool-alcoholic tendency, I'm turning over a new leaf - I think I can get by with two or three tools -

something that makes holes, such as a drill; drives screws (hey, a cordless "drill" also works - even more efficiency!) and, of course:

Thursday, June 14, 2018

Tuesday, June 12, 2018

Traffic in (and out) of a plywood plant

Most of the industries along the Central Vermont, at least in Vermont, can be summed up in one word - lumber.

Furniture makers, door and window manufacturers, and even ski and baseball bat manufacturers all had one thing in common - their raw material was primarily hardwoods harvested from the verdent Green Mountains. One could even say another famed Vermont product - maple syrup - was directly related to the lumber industry.

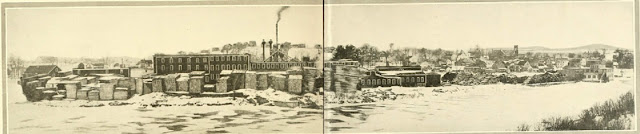

Furniture makers, door and window manufacturers, and even ski and baseball bat manufacturers all had one thing in common - their raw material was primarily hardwoods harvested from the verdent Green Mountains. One could even say another famed Vermont product - maple syrup - was directly related to the lumber industry. So it was no surprise to me when I learned one of the larger industries (click on photo above to enlarge) along the CV yard in Richford was a plywood manufacturing facility. Specifically, this particular plant specialized in making plywood shipping crates for shipping a variety of items, including "special talking machines."

So the outbound shipments are fairly obvious. Plywood crates, shipped flat in "shooks" (kind of like the Ikea of its day, I guess!) that can go almost anywhere other products are made.

But I'm wondering what, if anything, would be shipped in to the plant?

To make plywood you start with a log, strip the bark, and slice it into thin strips, called "plys."Glue is applied to the plys and they are stacked with the grain running alternate directions from one layer to the next and then they are subject to high temperature steam before the stacked plys are placed into a hydraulic press (below) that laminates the layers together forming, you guessed it, "plywood."

To make plywood you start with a log, strip the bark, and slice it into thin strips, called "plys."Glue is applied to the plys and they are stacked with the grain running alternate directions from one layer to the next and then they are subject to high temperature steam before the stacked plys are placed into a hydraulic press (below) that laminates the layers together forming, you guessed it, "plywood." The raw sheets are then heated and stacked to dry, and will eventually be cut to size and/or sanded before being shipped to the customer (the illustrations with this post came from a 1921 Atlas Co. brochure - you can find the entire brochure HERE).

I'm fairly certain the plant in Richford generated enough wood scrap that the boilers - visible at the location of the stacks in the photo above - were likely wood fired, but who knows - it's possible they were coal fired or the coal provided supplemental power to the plant.

"Adhesive" of some sort may also have been delivered to the plant - at least that seems fairly logical. I don't believe the plant received wood by rail, although it may have in earlier times or in the event a unique species of wood was needed.

Turning up the brochure has given me enough knowledge to press forward with planning how to model the industry on the layout.

Thursday, June 7, 2018

Model Railroad Hobbyist and Podcasts

Couple of quick updates -

Although I haven't written anything for a couple of years for Model Railroad Hobbyist, Joe Fugate asked me to participate in the 100th issue version of the "Getting Real" column. You can find that here:

http://mrhpub.com/2018-06-jun/online/

The fantastic images in that issue of Mike Confalone's latest visit to Allagash country are well worth your time.

The column produced some interesting comments - some of which went down a rabbit hole and led to some interesting, and widely divergent, commentary dealing with spouses, money, and the hobby.

And somewhat out of the blue Lionel Strang asked me to appear on his "A Modelers Life" podcast to update him on what I'm doing. We spent almost as much time talking about the Navy as we did model railroading. You can find it here:

https://www.amodelerslife.com/

A few weeks ago I got a short spot for an update on Tom Barbalet's Model Rail Radio (Show #141) podcast - you can find it here:

http://www.modelrailradio.com/

Although I haven't written anything for a couple of years for Model Railroad Hobbyist, Joe Fugate asked me to participate in the 100th issue version of the "Getting Real" column. You can find that here:

http://mrhpub.com/2018-06-jun/online/

The fantastic images in that issue of Mike Confalone's latest visit to Allagash country are well worth your time.

The column produced some interesting comments - some of which went down a rabbit hole and led to some interesting, and widely divergent, commentary dealing with spouses, money, and the hobby.

And somewhat out of the blue Lionel Strang asked me to appear on his "A Modelers Life" podcast to update him on what I'm doing. We spent almost as much time talking about the Navy as we did model railroading. You can find it here:

https://www.amodelerslife.com/

A few weeks ago I got a short spot for an update on Tom Barbalet's Model Rail Radio (Show #141) podcast - you can find it here:

http://www.modelrailradio.com/

Subscribe to:

Posts (Atom)