Wednesday, March 30, 2022

Monday, February 21, 2022

"Blocking" in Atlas Plywood

|

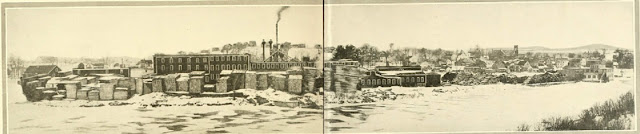

| Atlas Plywood in Richford is in the background. P. R. Hastings |

I do have the Sanborn Map that shows the footprint of the building, and a few photos. I've blogged about the plant previously - mostly in the post you can find HERE. That post covers the prototype - my goal this morning was to think through how to convert the information I have into a (compressed) model of the facility.

The brochure and Sanborn Map both date to the 1920s and early 30s. The only images I've found of the building after the war (it burned down in October 1954) were a partial view captured by Phil Hastings, and a quick snippet of the building on a DVD that was remastered from 8mm movie film shot from a moving caboose!

|

| Atlas Plywood - screen capture from a Central Vermont Railway in Steam DVD. |

It seemed pretty obvious that I wasn't going to find any more detailed images than I already had. Besides, a quick scaling of the map image of the facility (called Richford Mfg. on the 1920 Sanborn) revealed it was about 550 feet from stem to stern.

I'd left a large area for the model of the plywood plant - but building it full scale would completely dominant the view of the layout from anywhere in the room.

A compressed version of the plant seemed a better approach.

In the end I settled on a footprint about 36" long by 8" long at the widest point for the buildings themselves. That doesn't include some areas available for lumber stacks and the like.

I drew up a footprint that seemed to capture the key elements of the building. Some of the items I wanted to include were:

1. The two story section between the tracks in the map image

2. The walkway between it and the larger building.

3. The portion of the three story section with the three smokestacks.

4. The large two story area at the top of the image in the Sanborn Map.

Rather than try to draw a scale plan of the building I blocked these key elements.

The first draft of how this could look is shown below. I started by drawing the overhead "footprint" view. Then I carried the lines where the building went from two to three stories and the like and blocked into the basic shapes. It looks like this will fit well and produce a convincing impression of the complex.

Before committing this to styrene I need to mockup the building in three dimensions.

"Blocked in" sketch of how the key elements could be combined into a convincing compressed model of the prototype.

Thursday, December 26, 2019

Images from videos

Video #3 is actually two parts - the majority of the first half of the video shows lots of switching in Palmer and Willimantic, and then shifts to a ride in the caboose up the Richford Branch. (The second half of volume #3 is a cab ride on the Willimantic sub in Connecticut).

I was going through some boxes a couple of weeks ago and came across the DVD - which I haven't looked at in a number of years. I went ahead and popped it into the DVD player to see if there was anything useful to me. In short, there was. I did a few "screen captures" with my iphone - they actually turned out fairly decent - considering this was a DVD remastered from a VHS that was sourced from 8mm home movie shot with a handheld camera on a caboose that was bouncing around quite a bit. I've mentioned the Richford plywood plant (which burned in 1954) before - this is the only color image (and one of only a few views of any type!) of that plant I've seen, ever...

|

| Atlas Plywood in Richford, shortly before it burned to the ground in October 1954. |

|

| Approach into the CV's Richford Yard |

|

| Another "only time I've seen a photo of ..." - the HP Hood Creamery in Richford. |

|

| In Enosburg Falls, that's a coal dealer shed in the right foreground. |

|

| Enosburg Falls - note how tight this area was. Basically east of Main Street, West of Plesant Street. Feed mill, with a "Wirthmore Feeds" sign atop the roof barely visible to the left. |

Tuesday, June 12, 2018

Traffic in (and out) of a plywood plant

Most of the industries along the Central Vermont, at least in Vermont, can be summed up in one word - lumber.

Furniture makers, door and window manufacturers, and even ski and baseball bat manufacturers all had one thing in common - their raw material was primarily hardwoods harvested from the verdent Green Mountains. One could even say another famed Vermont product - maple syrup - was directly related to the lumber industry.

Furniture makers, door and window manufacturers, and even ski and baseball bat manufacturers all had one thing in common - their raw material was primarily hardwoods harvested from the verdent Green Mountains. One could even say another famed Vermont product - maple syrup - was directly related to the lumber industry. So it was no surprise to me when I learned one of the larger industries (click on photo above to enlarge) along the CV yard in Richford was a plywood manufacturing facility. Specifically, this particular plant specialized in making plywood shipping crates for shipping a variety of items, including "special talking machines."

So the outbound shipments are fairly obvious. Plywood crates, shipped flat in "shooks" (kind of like the Ikea of its day, I guess!) that can go almost anywhere other products are made.

But I'm wondering what, if anything, would be shipped in to the plant?

To make plywood you start with a log, strip the bark, and slice it into thin strips, called "plys."Glue is applied to the plys and they are stacked with the grain running alternate directions from one layer to the next and then they are subject to high temperature steam before the stacked plys are placed into a hydraulic press (below) that laminates the layers together forming, you guessed it, "plywood."

To make plywood you start with a log, strip the bark, and slice it into thin strips, called "plys."Glue is applied to the plys and they are stacked with the grain running alternate directions from one layer to the next and then they are subject to high temperature steam before the stacked plys are placed into a hydraulic press (below) that laminates the layers together forming, you guessed it, "plywood." The raw sheets are then heated and stacked to dry, and will eventually be cut to size and/or sanded before being shipped to the customer (the illustrations with this post came from a 1921 Atlas Co. brochure - you can find the entire brochure HERE).

I'm fairly certain the plant in Richford generated enough wood scrap that the boilers - visible at the location of the stacks in the photo above - were likely wood fired, but who knows - it's possible they were coal fired or the coal provided supplemental power to the plant.

"Adhesive" of some sort may also have been delivered to the plant - at least that seems fairly logical. I don't believe the plant received wood by rail, although it may have in earlier times or in the event a unique species of wood was needed.

Turning up the brochure has given me enough knowledge to press forward with planning how to model the industry on the layout.